Asus A8N-SLI Deluxe

Launched December 2005Inducted for The board that reintroduced SLI and catapulted Asus to number one spot for enthusiasts

There had been decent Asus motherboards prior to the A8N-SLI Deluxe, but this was the product that really made the firm’s fortune when it came to enthusiasts, beginning a period of dominance that continues to this day.

After the dreadful GeForce FX, Nvidia rebounded with the excellent GeForce 6-series, and it sought to press its advantage by making good use of the SLI trademark it had acquired when it bought 3dfx’s assets in a bankruptcy sale at the end of 2000. Initially, this new SLI was available on Xeon motherboards using an Intel E7525 chipset, as these were the only boards available that featured multiple high-speed PCI-E slots. However, within a month, Nvidia launched its own SLI chipset (and then of course, went on to try to lock down SLI, only bowing to the inevitable and allowing licensing on Intel X58 motherboards, and then P55).

Regardless of how SLI panned out, at launch, it presented a brand-new opportunity, which Asus seized with a brilliant initial design. The A8N-SLI Deluxe was significantly better than competing nForce 4 SLI boards – the PCI-E slots were spaced well apart, meaning that dual graphics cards were kept well away from one another, which helped with thermal management. It also allowed you to mod the single-slot GeForce 6800 GT with an aftermarket dual-slot cooler to keep your rig’s noise levels down. Asus also added features that were to become standard features on enthusiast-level boards, such as heatsinks for the VRMs, and it didn’t go overboard with 1x PCI-E slots, unlike some motherboards at the time.

Despite the fact that the SLI version of the nForce 4 was supposedly the high-end variant of the chipset, Asus got the price right. The motherboard cost £130 at launch – the same price as many competing boards with the non-SLI, nForce 4 Ultra chipset. Overclocking performance was good from the outset too. The board was a fantastic example of a launch product that was designed and priced right from day one, and Asus used the momentum it gained from the A8N-SLI Deluxe to secure its dominant position in the high-end motherboard market.

Armari XCP

Launched August 2008Inducted for Services to awesomeness

There’s liquid cooling, and then there’s liquid cooling. Building a water-cooled PC with pipes, pumps and blocks is one thing, but building a PC in which all the key components are entirely submerged in liquid is a different proposition. While contact with water is fatal for electrical components, contact with liquid isn’t, as long as the liquid isn’t conductive. Cooking oil, for instance, has extremely low conductivity, and enthusiasts have experimented with ‘full immersion’ computers for several years. However, the majority were little more than a bunch of old components in a tub full of oil, meaning that they were ugly, and had no thought of cooling the oil aside from natural convection.

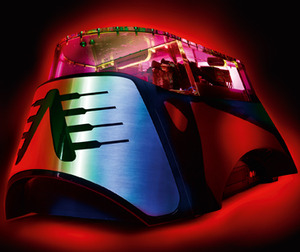

Armari won the Dream PC competition in 2005, and planned to follow up its victory with a full immersion PC, but it wasn’t until 2008 that it was happy enough with its machine to show it to the public. The XCP was stunning to behold – as we wheeled it through the building, it continually attracted people’s attention – thanks to a design that featured a clear acrylic tank on top showcasing the motherboard and main components, which rested on a Darth Vader-esque black shell, concealing all manner of cooling technology.

Unlike homemade full immersion PCs, the XCP actively cooled the inert liquid, using a custom-engineered tubing system and two mammoth triple 120mm-fan radiators. Armari overcame so many substantial design challenges that it was hard to believe the XCP was real. Consider the fact that the inert coolant, Fluorinert, is significantly denser than water, meaning that the PC was ludicrously heavy (it required four people to lift it when empty, and when filled, it was to all intents and purposes, completely immobile). The density meant that standard water-cooling pumps couldn’t circulate the liquid. As it evaporates at room temperature, the tank has to be airtight; as it expands and contracts when it heats and cools, the entire system has to be pressure-sealed, and instead of standard tubing, Armari had to use Teflon lined 1/2in metal tubes so that they wouldn’t crack.

The XCP was amazing to behold – particularly in the way that the heat from the components caused the coolant to roil, with the turbulence clearly visible in the tank. It was an amazing example of PC engineering that was hugely impressive and inspiring. Check out our archived video from CPC to see the XCP in action.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.